Do you struggle with updating your lubrication procedures within your CMMS? In this video, Paul shares how LubePM‘s Dynamic Procedures lets you update procedures in real-time.

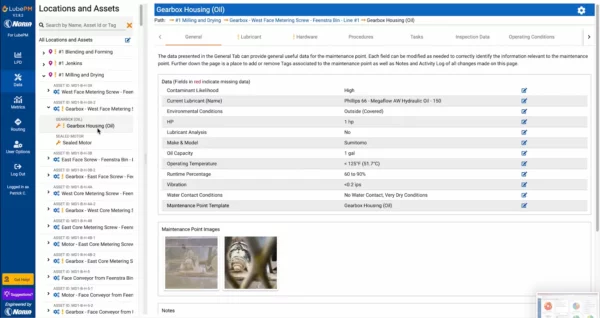

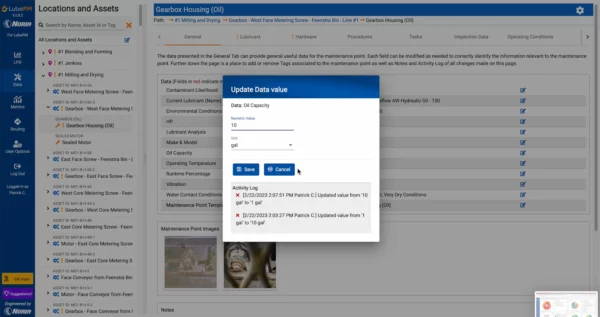

As you update fields in your maintenance point data, it automatically updates fields in the procedures throughout LubePM and the routing functionality.

Streamlining Maintenance Procedures with Lube PM’s Dynamic Functionality

Introduction

Maintenance management is an essential part of keeping your industrial equipment running smoothly. However, one common challenge that maintenance professionals face is keeping their lubrication procedures current within their Computerized Maintenance Management Systems (CMMS). The process can be time-consuming and prone to errors, leading to inefficient operations and increased downtime. But what if there was a solution that could automatically update your lubrication procedures as you make changes to your maintenance data? Enter Lube PM’s dynamic procedure functionality.

Lube PM’s Dynamic Procedure Functionality

In a video transcript that caught our attention, a representative from Lube PM introduces their innovative solution to the problem of maintaining up-to-date lubrication procedures within your CMMS. This dynamic procedure functionality promises to revolutionize how you manage lubrication processes, making it easier and more efficient than ever.

Automated Updates

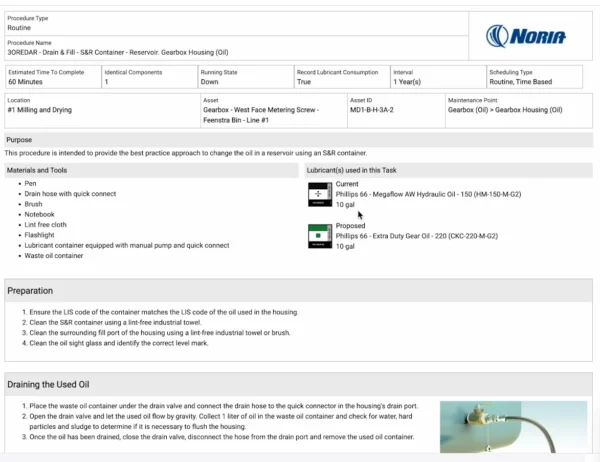

The core feature of Lube PM’s dynamic procedure functionality is its ability to update procedure fields as you change your maintenance data automatically. This includes both maintenance-point data and routing functionality. In the video, the presenter demonstrates how simple and effective this process is.

Benefits of Lube PM’s Dynamic Procedure Functionality

- Time-Saving: One of the most significant advantages of using this dynamic procedure functionality is the time it saves. Maintenance personnel will no longer need to update procedures, which can be time consuming when performed manually. This automated process streamlines the entire maintenance workflow.

- Error Reduction: Manual updates are time-consuming and prone to errors. Automating the procedure updates eliminates the risk of inaccuracies, ensuring that your maintenance procedures are always aligned with the latest data.

- Efficiency: With Lube PM’s dynamic functionality, your maintenance team can work more efficiently. They can spend less time on administrative tasks and more on maintenance work, ultimately increasing overall productivity.

- Simplicity: The process of updating procedures is straightforward and user-friendly. As shown in the video, it’s as easy as making the necessary changes and hitting save. There’s no need for extensive training or technical expertise.

Conclusion

In a world where efficiency and accuracy are critical in industrial maintenance, Lube PM’s dynamic procedure functionality offers a promising solution to a common problem. This tool can significantly improve your maintenance operations by automating procedure updates and ensuring they align with your maintenance data. To learn more and request a LubePM demo, go to: https://lubepm.com/#contact