With many senior employees retiring, it’s more important than ever to make sure that you have proper documentation of your plant’s assets. Do you have a way to store machine information so new employees can confidently maintain your equipment? LubePM can help with that, with detailed machine information that helps ensure the right equipment is getting lubricated in the right place and with the right lubricant – every time.

Bridging the Gap: LubePM — The Solution for Transitioning Workforce in Industrial Plants

Introduction

In today’s ever-evolving industrial landscape, one significant challenge many companies face is the retirement of senior workers, particularly in lubrication. As these seasoned professionals bid farewell to their careers, they leave behind a wealth of knowledge and expertise that can be difficult to replace. However, the transition doesn’t have to be daunting, thanks to innovative solutions like LubePM.

There is a common theme in industrial lubrication where senior employees, who have been the backbone of lubrication tasks in industrial plants, are retiring. With their departure, companies need to bring in new employees to perform these crucial tasks, and that’s where the challenge lies.

The newcomers may find themselves in unfamiliar territory, needing to learn the ins and outs of the industrial plant or even where specific machinery is located. This knowledge gap can lead to inefficiencies, increased downtime, and, in some cases, costly mistakes. Fortunately, LubePM has emerged as a game-changing solution to bridge this knowledge gap.

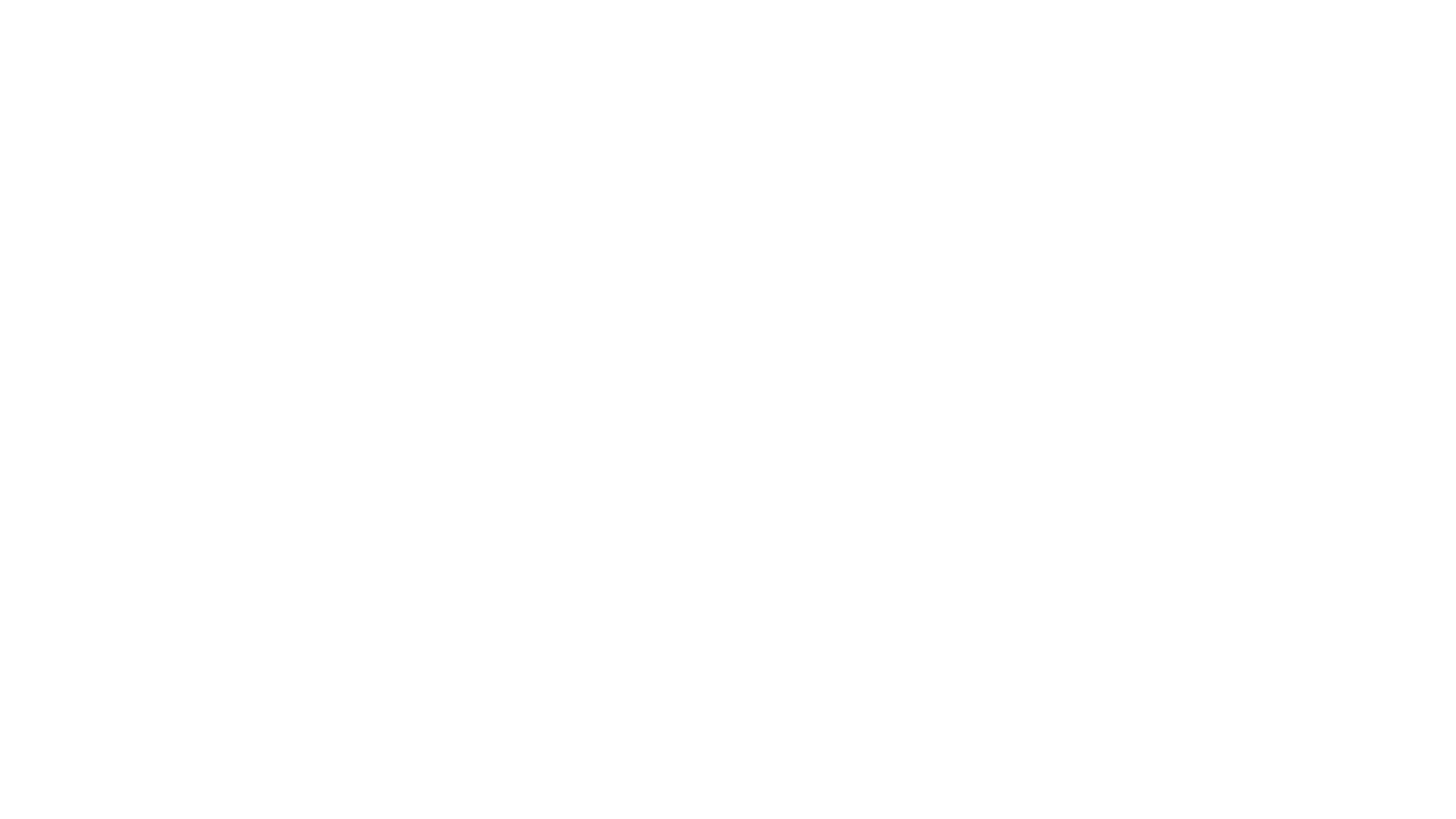

LubePM is a powerful software platform designed to streamline lubrication processes and ensure that the right machinery gets the necessary care and maintenance. How does it work? Let’s break it down.

Machine Identification

LubePM allows users to access a comprehensive machinery database within the industrial plant. With just a few clicks, new employees can easily identify a machine, access its specifications, and understand its specific lubrication requirements. This is invaluable for employees who may not be familiar with every piece of equipment in the facility.

Machine Profile Pictures

A picture is worth a thousand words, and it can save you valuable time and resources in the industrial world. LubePM provides machine profile pictures, helping employees put a face to the machinery they’re working on. This visual reference simplifies the identification process, making it easier for newcomers to ensure they’re at the right machine.

Inspections and Lubrication

One of the primary objectives of LubePM is to ensure that inspections and lubrication activities are performed on the correct machine. The software helps streamline the workflow, prompting users to input data specific to the machine they are working on, reducing the risk of errors and improving overall efficiency.

Conclusion

The bottom line is that LubePM simplifies the transition process for industrial plants by ensuring that lubrication tasks are carried out effectively and efficiently. It is a guiding hand for new employees, helping them overcome the hurdles of knowing the plant’s layout and the machines they are working on.

If you’re in an industrial plant facing the challenge of transitioning your workforce, LubePM is the solution you’ve been looking for. It’s a powerful tool that improves efficiency and reduces the learning curve for new team members.

Don’t let the retirement of senior workers be a roadblock in your path to success. Embrace the future of lubrication with LubePM. To learn more and request a LubePM demo, go to: https://lubepm.com/#contact