Are longevity and machine performance related to an organization’s lubrication management program?

Yes, and at the heart of every effective lube program is a Lubrication Management System (LMS) used to optimize and centralize a vast amount of data.

Selecting the best software for your facility’s LMS needs is paramount and the one you choose should help your maintenance teams:

- Effectively identify and track plant-wide areas of opportunities related to the lubricant lifecycle

- Efficiently collect/import pertinent asset data to yield precise lubricant and hardware recommendations

- Expertly perform inspection and lubrication tasks via detailed, illustrated procedures

- Electronically report feedback and raise alerts to management

- Easily integrate lubrication work with existing CMMS software

- Externally access plant data for custom functionality via APIs and/or exported spreadsheets

- Effortlessly scale your lubrication program to match business growth

While others in the space are just now emerging as self-proclaimed leaders in the realm of lubrication management, LubePM has long stood at the forefront of the competition with the backing of decades long machinery lubrication experience from Noria Corporation. LubePM is lubrication management software engineered by lubrication management experts and ICML certified software engineers.

When it comes to selecting the right software for lubrication management that checks all the boxes listed above, the choice is clear.

Why LubePM is the Best Choice

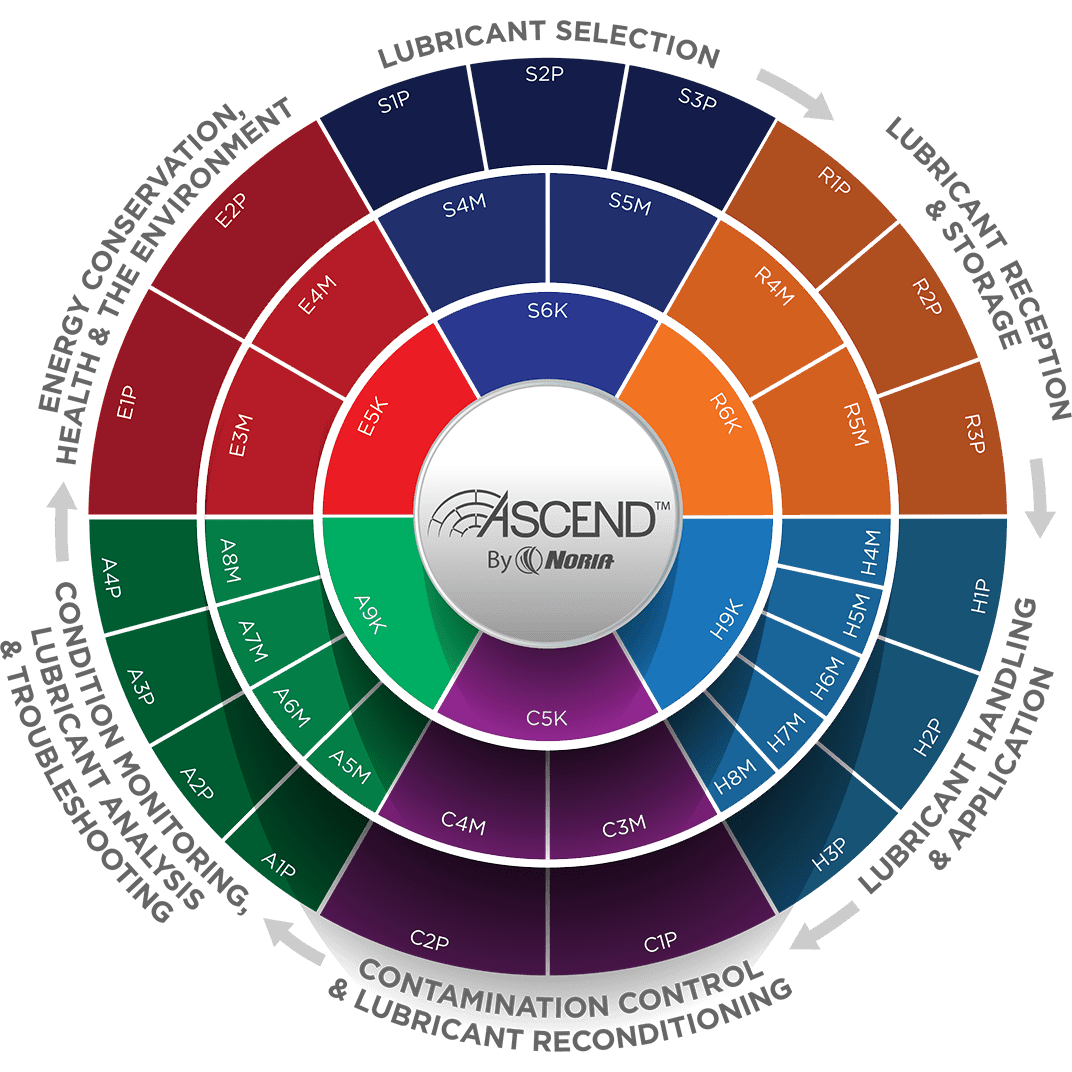

Ascend Assessment

A lubrication expert conducts a comprehensive evaluation of your current lubrication practices across the six stages of the lubricant lifecycle, establishing a baseline to track program enhancements over time. The assessment produces a score for the plant and an Ascend chart, comprised of 40 critical lubrication factors. Noria also provides plant leadership and management with a complete SWOT analysis, metrics, and KPI recommendations. These deliverables as well as a prioritized roadmap of improvement recommendations are all housed within the LubePM software’s web platform. As initiatives are completed and recorded in the platform, the plant’s score is adjusted accordingly. Corporate leadership can also compare the scores across all their plants via a custom dashboard.

Engineering Design

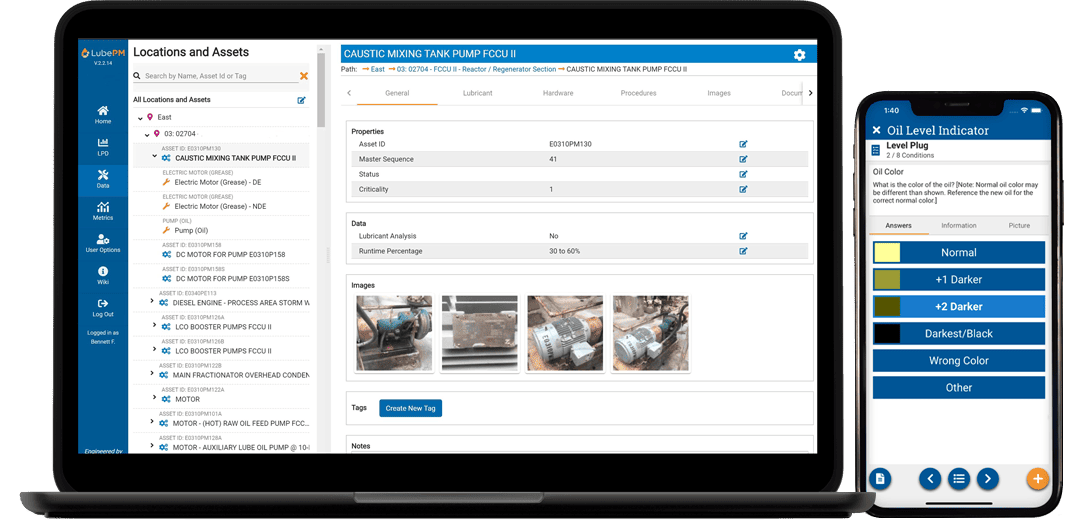

A LMS is only as good as the data it runs on and LubePM provides various methods to accomplish getting your asset information into the platform. Templates can be provided to import your asset list, or information can be transferred from your existing CMMS software. Noria consultants can then visit your plant and perform a detailed survey of all your equipment and ambient conditions. If you are more the DIY type, you can collect the data locally via the Site Builder in the LubePM mobile app. Regardless of the method you chose, once the data is uploaded to the web platform, our proprietary AI engine goes to work, crunching numbers and analyzing the data to produce smart recommendations and dynamic procedures tailored to each of your assets.

Smart Recommendations

Plant environments not only vary across industries but also within your own facility, where the same types of equipment may operate under diverse conditions. LubePM takes these variations into consideration when proposing lubricants for your plant so you can rest assured that every piece of equipment will be prescribed the right type and amount of lubricant. In addition to lubricants, the platform also provides hardware modification recommendations. LubePM also enables you to record and track the progress of your lubricant and hardware changes.

Dynamic Procedures

LubePM crafts procedures with detailed steps on performing lubrication and inspection tasks based on the lubricant type and hardware configuration of each of asset. When the configuration of an asset changes, LubePM dynamically alters the procedure steps or the entire procedure to reflect the current hardware and lubricant specified for the asset. These procedures are also packed with detailed pictures and illustrations to guide you when performing these tasks on your PM routes. For visual learners, a video procedure library is also available for common lubrication tasks. While LubePM provides out of the box procedures for lubrication, inspection, hardware modification, sampling, and other on-condition tasks, you can also create custom procedures for your facility’s special requirements.

Routing and Feedback

Planners can schedule maintenance tasks to lube techs via routes on the LubePM web platform. A convenient calendar view is provided to make scheduling and balancing workloads easy with drag and drop functionality. Once routes are scheduled and assigned, the techs download their assigned routes on the LubePM mobile app and go out into the plant to perform the work. A route can have a mix of tasks per maintenance point and for each task, the tech has access to the full procedure document. The document details the necessary materials, tools, and lubricant required to perform the task. Technicians can input the amounts of oil or grease added and even take notes and capture photos of the assets while executing a task. Got a particular issue that needs to be highlighted? Simply markup the photo with the built-in annotation tools.

Inspection tasks are a breeze in the LubePM mobile app. For these tasks, the technician is given a list of conditions to examine with a list of answer choices, making it extremely easy to capture the current state of the equipment. All this functionality works on a mobile device even when it is disconnected from the internet. An internet connection is only required when downloading or uploading a route. Upon upload, the data captured by the technician is processed by the web platform. Any anomalies found during inspections are shown as alerts in the platform and all photos and notes can be viewed for each task. Management can review this feedback and react accordingly with corrective action steps.

Seamless Integration and Scalability

Often, organizations are already heavily invested in various maintenance management systems and adopting new software can come across as a daunting undertaking. Fortunately, LubePM is designed to complement your existing systems by providing ways to work with them in tandem. Our software engineers are continuously innovating and looking to partner with labs to pull in oil analysis reports as well as integrating with CMMS’ like Maximo and SAP to report pertinent lubrication task data generated in the platform. Your data is your data and LubePM not only provides exportable spreadsheets but also offers an API for those seeking to develop their own custom integrations. With these features, LubePM facilitates the seamless cohabitation/collaboration with other software already in your ecosystem. As a cloud-based system, our software is scalable, allowing you to account for new equipment and lubrication needs as your organization expands.

Lubrication Excellence

Noria believes that lubrication excellence is a catalyst to remarkable machine reliability and have made a mission to inspire change through education by providing tools, resources, and expertise. A true Lubrication Management System prioritizes a plant’s successful lubrication journey rather than attempting to be a mediocre end all be all solution. When so much of your business relies on the uptime of your machinery, lubrication excellence is of utmost importance. LubePM delivers on that excellence.

Ready to take your maintenance program to the next level with LubePM? Reach out to a LubePM rep today.