Effective lubrication management is critical to the longevity and performance of machines. When plants scale up to meet demand, there is a need for greater efficiency and organization when it comes to maintenance tasks, and managing lubrication manually becomes less feasible. Enter Lubrication Management Software (LMS) – a platform designed to streamline and enhance the entire lubrication process. But what exactly is LMS, and why is it so essential?

Understanding LMS

Lubrication Management Software is a digital platform that helps organizations monitor and optimize their lubrication programs. It enables maintenance teams to ensure their machines receive proper lubrication at the right intervals, using the right lubricants. The platform also aids in performing visual inspections of lubricants, documenting lubricant inventory, getting hardware recommendations, and developing procedures.

By centralizing lubrication tasks into a single system, you eliminate the need for pencil and paper record-keeping, which can be time-consuming and prone to errors. The software also integrates with existing maintenance systems, allowing teams to have a complete overview of lubrication program success and machine health.

What can it do?

Lubrication Management Software (LMS) offers a range of features designed to optimize lubrication processes. By centralizing data and automating tasks, the platform improves accuracy, accountability, and overall maintenance performance. Below are some key features that make it an essential tool for any lubrication program:Monitor Lubricant Use and Eliminate Waste: Track lubricant consumption across all machines, helping teams monitor usage patterns and identify areas where lubricant waste can be reduced. By optimizing lubricant application based on actual machine needs, organizations can avoid over-lubrication, reduce costs, and improve environmental sustainability.

Monitor Lubricant Use and Eliminate Waste

Track lubricant consumption across all machines, helping teams monitor usage patterns and identify areas where lubricant waste can be reduced. By optimizing lubricant application based on actual machine needs, organizations can avoid over-lubrication, reduce costs, and improve environmental sustainability.

Implement Task-Oriented Accountability

Assign specific lubrication tasks to individual team members to make sure each step in the lubrication process is completed accurately and on time. This task-oriented approach creates accountability within maintenance teams—a necessity for a successful lubrication program.

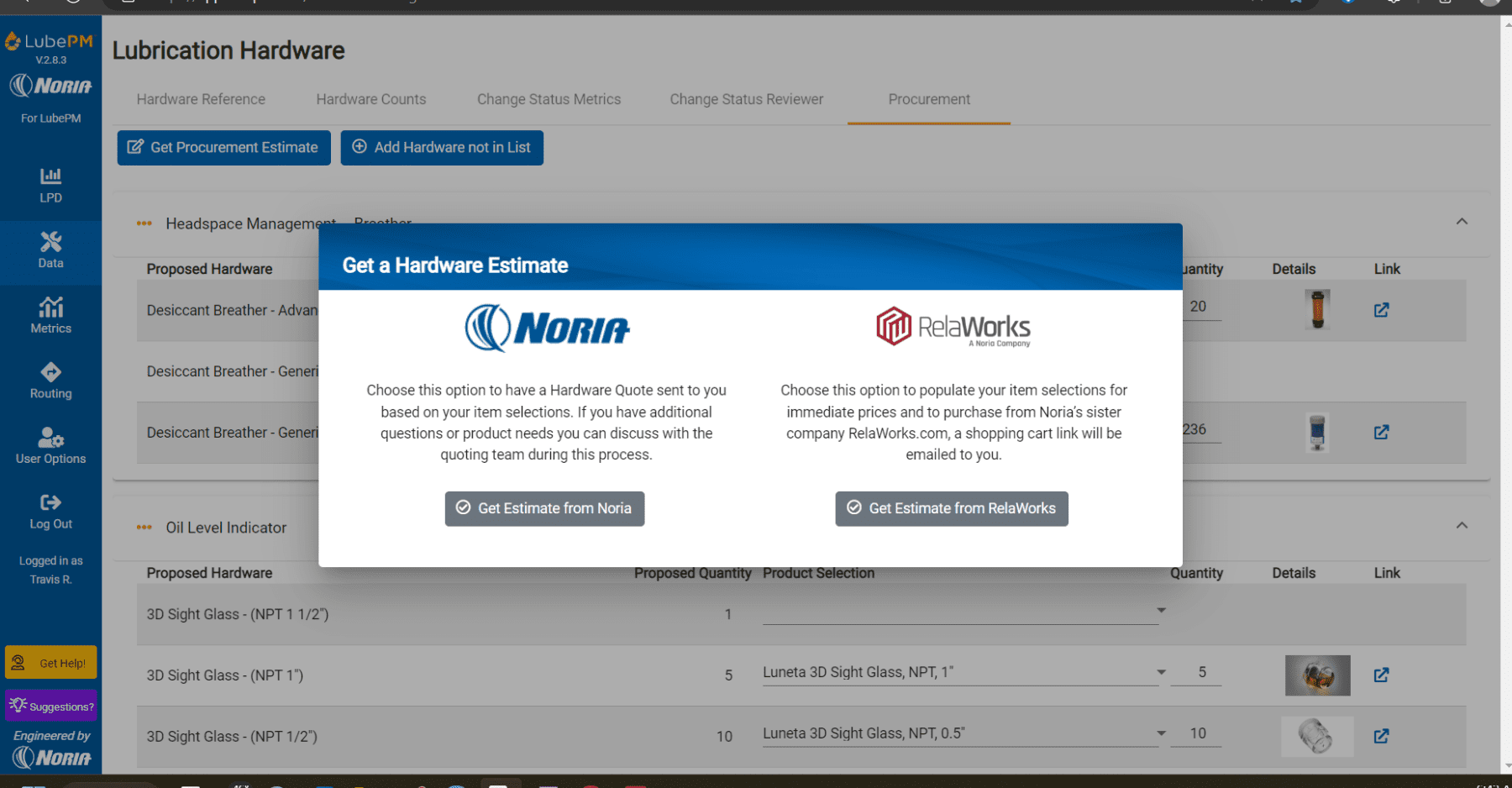

Provide Hardware Recommendations

By analyzing lubrication data, you can identify equipment that may benefit from hardware modifications, such as installing desiccant breathers, BS&W bowls, or sight glasses.

Track Program Cost Savings

One of the significant advantages of LMS is its ability to track the financial impact of a well-managed lubrication program. The software provides detailed insights into cost savings related to reduced lubricant consumption, extended equipment life, and minimized downtime. These metrics help justify investments in lubrication management improvements and demonstrate the value of the program.

Create and Trend Lubrication Data Points

Collect and trend critical lubrication data, such as oil analysis results, lubricant conditions, and consumption rates. By creating historical data points, maintenance teams can identify trends, predict potential issues, and make informed decisions to optimize lubrication schedules and extend equipment life.

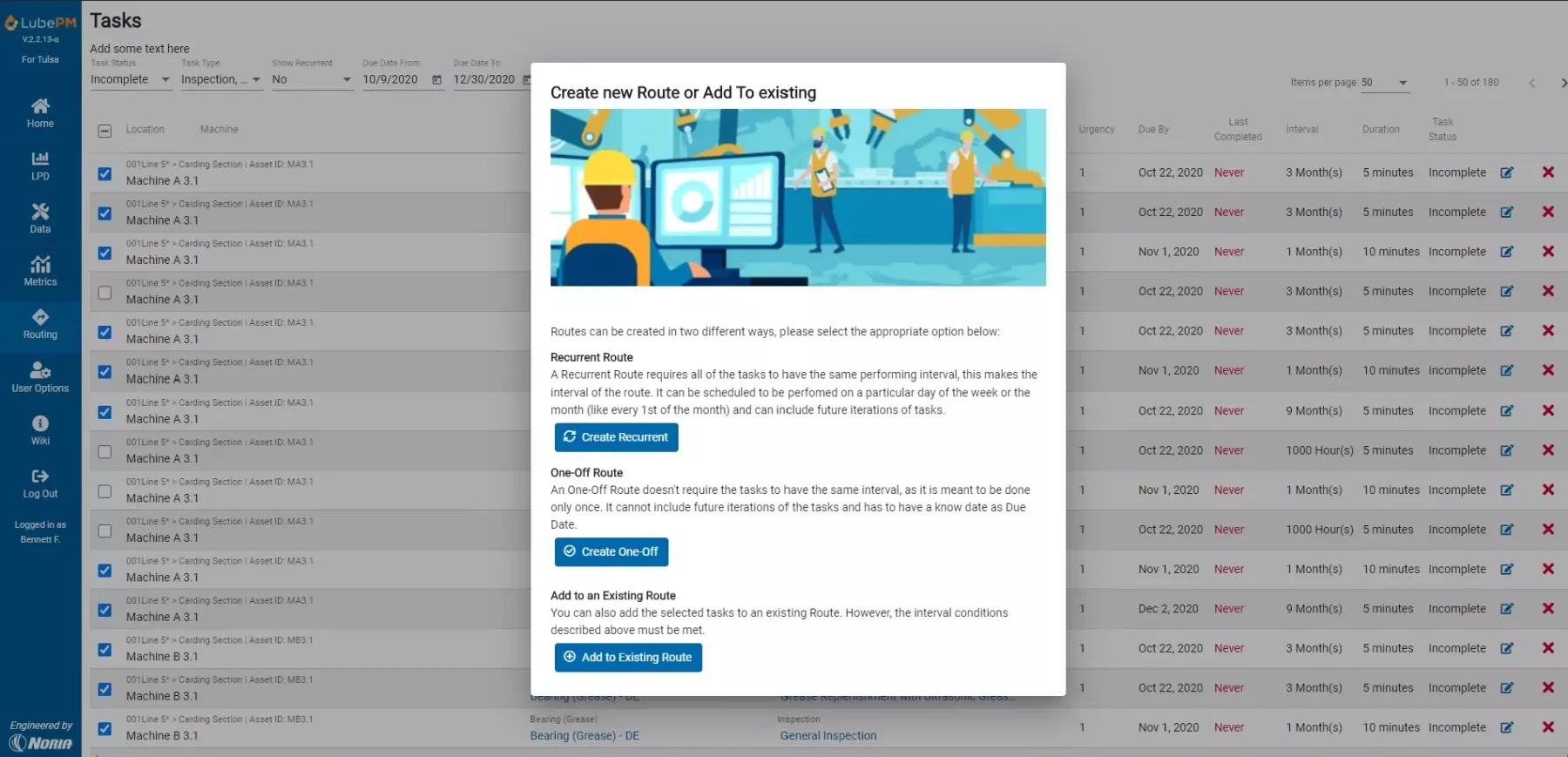

Schedule Routes and Enable Procedure Assignments

LMS enables the creation of dynamic lubrication procedures that adjust based on real-time data and changing conditions. For example, if a new asset is added in the system, procedures to inspect and relubricate that asset based on its requirements will automatically be created.

These features make Lubrication Management Software an invaluable tool for organizations looking to streamline lubrication practices, reduce costs, and improve overall equipment reliability.

Who Should Be Using LMS?

Any organization with complex equipment, high-value assets, or stringent maintenance requirements can greatly benefit from implementing Lubrication Management Software. This includes sectors where machine uptime and performance are critical to success, including:

- Manufacturing

- Oil and gas

- Energy

- Mining

- Pulp and paper

- Food and beverage

Facilities with large equipment or diverse machine types particularly stand to gain from the centralization, automation, and data-driven insights provided by an LMS. Additionally, companies with strict regulatory compliance standards, such as those in environmentally sensitive areas, can leverage the software to ensure adherence to lubrication protocols and reporting requirements. Whether a small maintenance team or a large, multi-site operation, any organization looking to optimize maintenance efficiency, reduce downtime, and improve equipment reliability should consider adopting an LMS as part of their maintenance strategy.

Why LMS is Essential

Managing lubrication manually is not only labor-intensive but also inefficient and risky. Human error, whether it’s missing a lubrication interval or applying the wrong lubricant, can lead to breakdowns. These failures often result in unplanned downtime, which can have a domino effect on productivity and operational costs. Here are several reasons why Lubrication Management Software is critical for modern maintenance strategies:

- Reduces Human Error: One of the main challenges of pen and paper lubrication management is the potential for human error. Missed lubrication intervals, improper lubricant application, or using the wrong type of lubricant can lead to significant issues like machine wear, overheating, and even catastrophic failure. LMS reduces the chances of these errors by automating lubrication schedules, tracking lubricant types, and making it easy to access and follow the correct procedures.

- Enhances Compliance: In industries where regulatory compliance is required, LMS helps ensure that lubrication processes meet all necessary standards. The software automatically logs all lubrication activities, generating detailed reports that can be used for audits or regulatory purposes. This record-keeping also improves internal accountability, as each task is tracked and assigned to specific team members, so nothing is overlooked.

- Enables Scalable Lubrication Programs: As organizations grow, managing lubrication across hundreds of assets can become increasingly challenging. LMS allows maintenance teams to scale their lubrication programs seamlessly by centralizing data and automating processes. Whether managing a handful of machines or an entire plant, it provides the tools necessary to maintain consistent lubrication standards across all equipment.

Bottom Line

Lubrication Management Software is transforming the way industries approach lubrication. By automating critical processes, improving accuracy, and providing valuable insights, the software offers significant advantages in terms of operational efficiency and equipment longevity. In an increasingly digital world, LMS is not just a tool for streamlining lubrication—it’s an essential component of modern maintenance management.

Want to learn more about using Lubrication Management Software (LMS) to improve your maintenance strategy?

Contact us to schedule a LubePM demo.