Why Choose LubePM?

Optimize equipment reliability with a dedicated lubrication management system

Unlock the Full Potential of Your Lubrication Program

As a Lubrication Management System (LMS) engineered by lubrication professionals, LubePM helps an organization create accountability to ensure that every lubrication point is carefully maintained, inspected and measured.

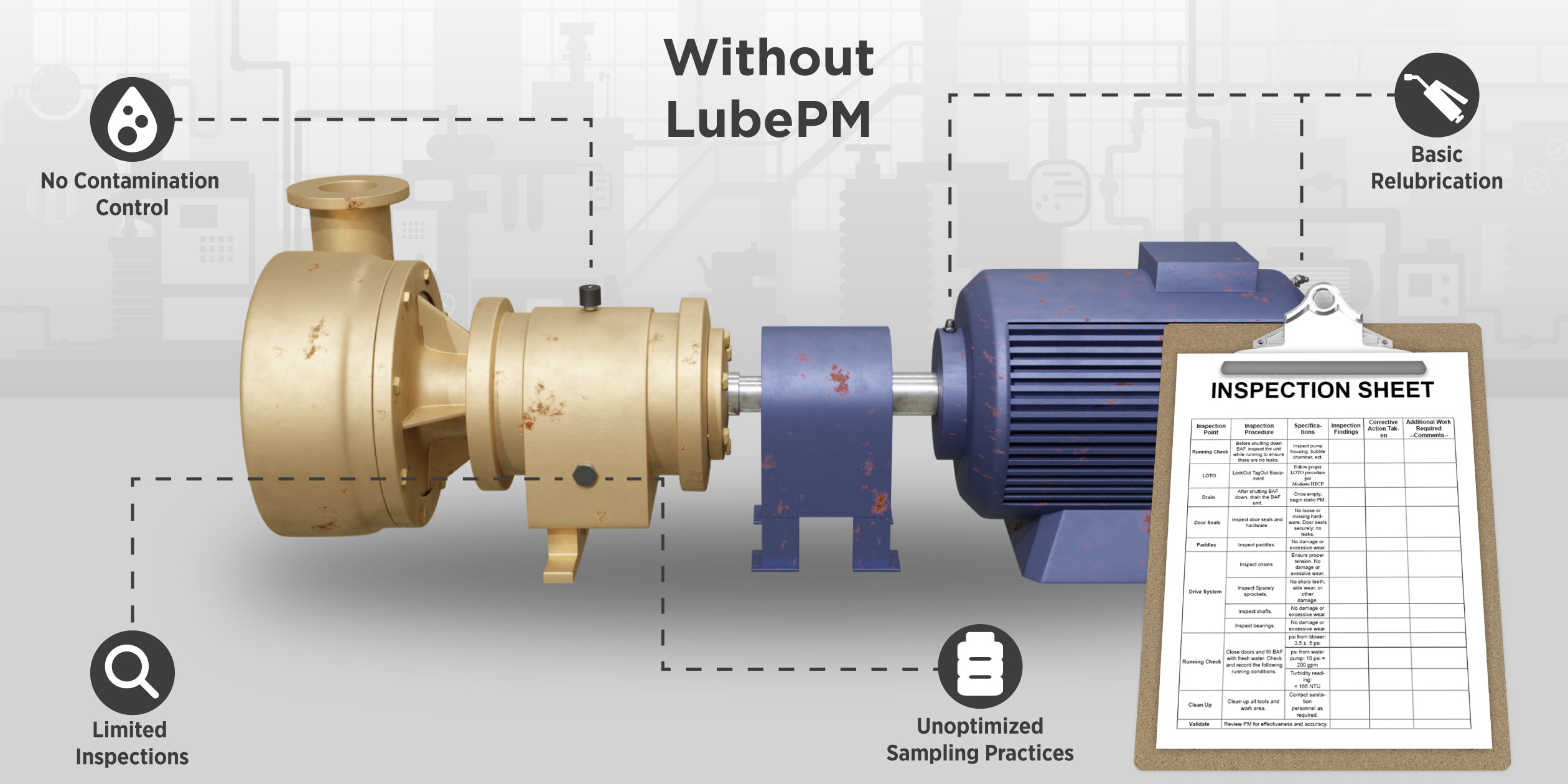

Without the enabling resource of a full-scale LMS, plants are susceptible to faulty and incomplete lubrication.

A CMMS falls short because it:

- Does not provide the necessary depth for a modern precision maintenance program; and

- Does not provide adequate job planning, task management and inventory control

LubePM can provide the necessary information and programmatic features to enable lubrication to serve as a pillar of precision maintenance and world-class reliability.

Before & After LubePM

See how LubePM can jumpstart your lubrication program

Before LubePM, lubrication programs were often reactive, fragmented, and dependent on outdated tools like spreadsheets or limited CMMS modules. Missed tasks, inconsistent practices, and poor visibility left equipment vulnerable to failure. After LubePM, lubrication becomes a proactive, precision-driven process. Teams gain access to optimized contamination control, Inspection 2.0, best practice relubrication, and live zone sampling integration—all within a centralized, cloud-based system. The result is a smarter, more accountable lubrication program that supports reliability and performance at every level.

Solutions Center

Everything you need to build a world-class lubrication program

Site

Lubricant List

View the “always current” plantwide lubricant list while managing changes for consolidation and best practices with integrated approval processes.

Schedule

Routes Immediately

View and schedule routes at a glance with the scheduling feature.

Accelerated

World-Class Improvement

Jumpstart your data import with asset-specific Noria recommendations for hardware modifications, lubricant selection, procedures and more.

Frequently Asked Questions

Answers to common questions about LubePM and lubrication management

What are the key features of LubePM?

LubePM auto-generates tasks with step-by-step procedures and vital lubricant information, ensuring you never miss an inspection point or use the wrong grease. It documents and saves your work on a cloud-based system for your team to access anytime, anywhere. It also provides real-time reporting and analytics, enabling you to make informed decisions about your maintenance program.

What is LubePM and how can it help my organization?

LubePM is a Lubrication Management System (LMS) engineered by lubrication professionals. It helps an organization create accountability to ensure that every lubrication point is carefully maintained, inspected, and measured. It provides the necessary information and programmatic features to enable lubrication to serve as a pillar of precision maintenance and world-class reliability.

How does LubePM differ from a traditional CMMS?

A traditional CMMS may not provide the necessary depth for a modern precision maintenance program and may lack adequate job planning, task management, and inventory control. LubePM, on the other hand, is designed to serve lubrication requirements completely and with the necessary precision.

Is LubePM just another checklist?

We have multiple options but most elect to use our mobile app for iPhone, iPad, and Android™️ and web platform to collect inspection results and record the execution of tasks in a simple-to-use digital format.

iPhone and iPad are registered trademarks of Apple Inc., registered in the U.S. and other countries.

Android is a trademark of Google LLC.

We have a spreadsheet for lubrication, is this good enough?

Spreadsheets and notebooks are common but are difficult to maintain and update. Utilizing our solution makes this easy with instant updates.